Silica powder is dust recovered from the smelting of metallic silicon or ferrosilicon alloys. Its primary component is silicon dioxide. As an important inorganic non-metallic material, silica powder possesses excellent physical and chemical properties, including small particle size, light weight, large specific surface area, and high refractoriness. It is widely used in rubber, ceramics, refractories, chemicals, concrete, and other fields.

Use the table of contents below to navigate through the guide:

1Applications in Concrete

Silica powder's application in the concrete industry is an area where research into its recycling and utilization has been early, fruitful, and widespread both domestically and internationally. Its excellent physical and chemical properties are primarily leveraged as an admixture in concrete, effectively improving various concrete properties.

2Applications in Refractory Materials

High-Performance Refractory Materials: High-quality silica powder is primarily used in high-performance refractory castables, precast components, ladle linings, air-permeable bricks, self-flowing refractory castables, and wet and dry spraying materials.

High-Temperature Ceramics: In high-temperature ceramics, silica powder provides high fluidity, low water retention, high density, and high strength, thereby enhancing the strength and wear resistance of sintered products.

High-Temperature Ceramics: In high-temperature ceramics, silica powder provides high fluidity, low water retention, high density, and high strength, thereby enhancing the strength and wear resistance of sintered products.

3Applications in Cement

Cement Raw Materials: Microsilica powder can be used as a cement raw material. Adding 18%-25% microsilica powder to cement raw materials can increase cement kiln output (by 10%-20%) and cement quality (for example, increasing compressive strength from 47 MPa to 54-56 MPa).

4Applications in Polymer Materials (Plastics, Rubber, and Coatings)

Filler Function: Silica powder, as a non-metallic mineral filler, plays an important role in polymer materials (plastics, rubber, and coatings, among others). Adding silica powder to polymer base materials not only reduces costs but also improves material properties (such as compression resistance, impact resistance, corrosion resistance, flame retardancy, and insulation) and dimensional stability, while also imparting unique physical and chemical properties.

5Applications in Other Industrial Fields

Metallurgy, Chemical Industry, and Environmental Protection: Microsilicon powder, due to its excellent physical and chemical properties, is widely used in these fields.

Agricultural Fertilizer: Microsilicon powder can be mixed with potassium hydroxide or potassium carbonate and heated to produce slow-release agricultural fertilizer potassium silicate. This fertilizer resists volatilization, protects the soil, promotes crop root development, and suppresses pests and diseases. Microsilicon powder also prevents fertilizer from clumping.

Agricultural Fertilizer: Microsilicon powder can be mixed with potassium hydroxide or potassium carbonate and heated to produce slow-release agricultural fertilizer potassium silicate. This fertilizer resists volatilization, protects the soil, promotes crop root development, and suppresses pests and diseases. Microsilicon powder also prevents fertilizer from clumping.

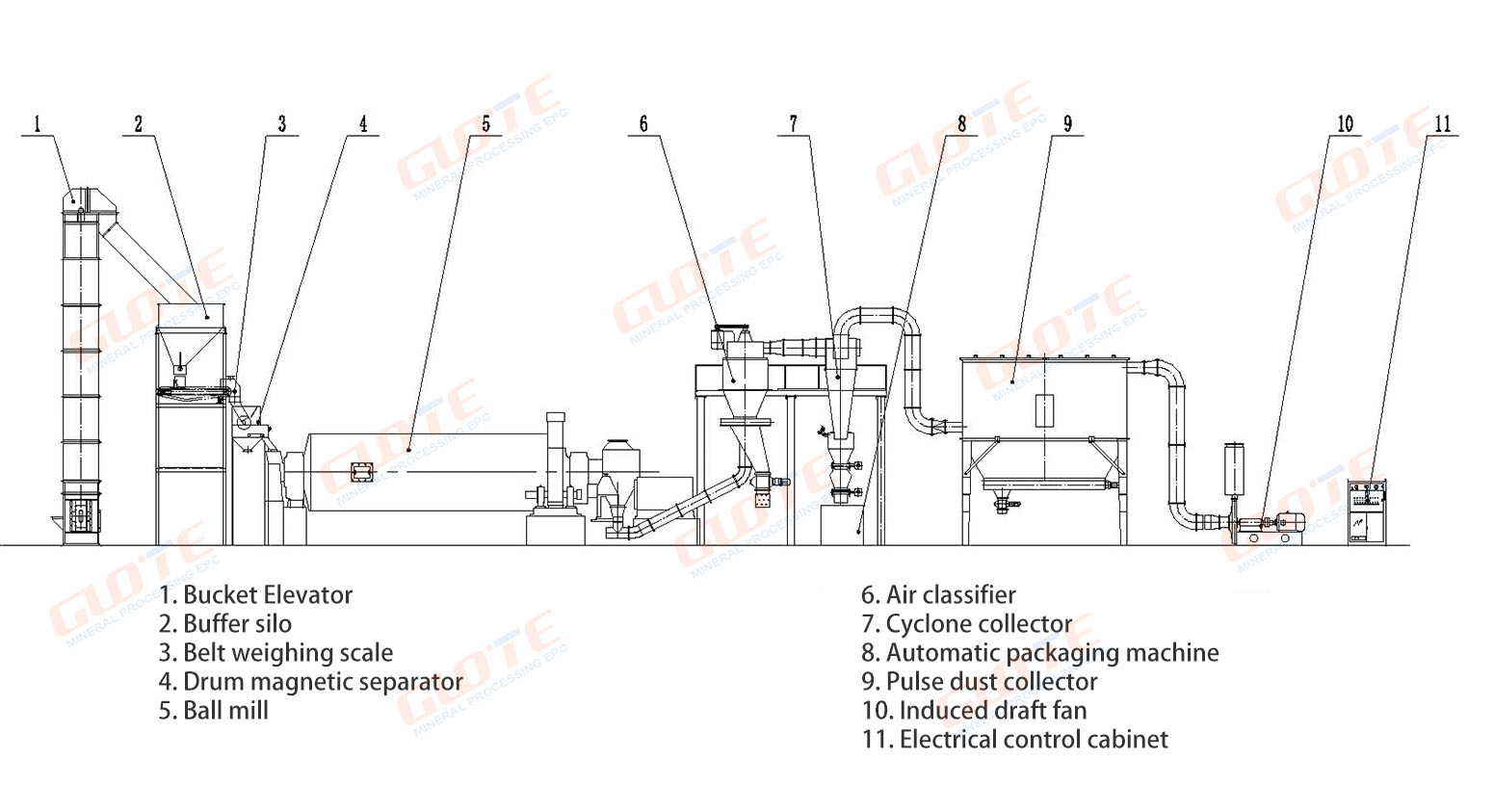

6Guote's Silicon powder production line

[Overview]: Silica powder (quartz powder) production line is a complete set of process equipment that processes quartz raw materials (quartz sand, quartz stone, etc.) into silicon dioxide powder with different particle sizes and purity requirements. Its core goal is to achieve efficient, precise, stable and environmentally friendly production.

[Production line advantages]: This production line is an organic combination of high-purity sand grinder crushing technology, ball mill grinding technology, and airflow classification technology, which can give full play to their respective technical advantages.

[Production line advantages]: This production line is an organic combination of high-purity sand grinder crushing technology, ball mill grinding technology, and airflow classification technology, which can give full play to their respective technical advantages.

-

PRE

Process characteristics and process of quartz stone pickling

Quartz pickling is the core process of quartz sand purification. It dissolves metal oxides, silicate…

-

NEX

Repair and maintenance of mining machinery and equipment.

The daily maintenance of mining machinery can be roughly divided into three types: cleaning maintena…

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE