Technology

Modern mineral processing lines benefit from cutting-edge technology, embodied in customized, streamlined processes and high-quality equipment. Guote Mining Equipment is deeply aware of the importance of technology to business development. Therefore, the company has established a mineral analysis laboratory, a mineral processing planning and production line design department, and a technical production and R&D department to provide strong technical support for the smooth development of sales operations and the comprehensive implementation of its "mineral processing EPC+M+O" service.

OUR ADVANTAGE

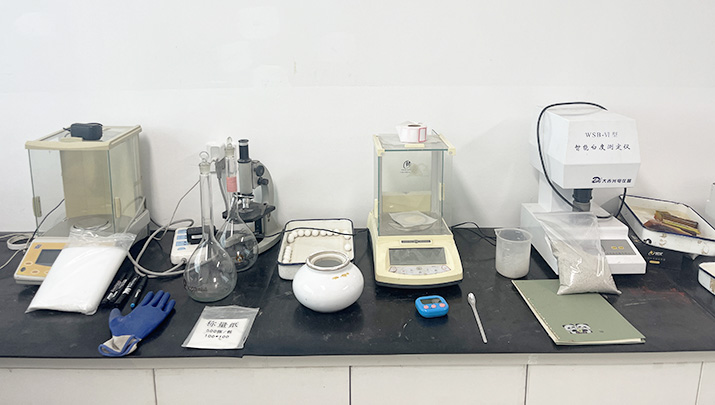

Mineral Analysis Laboratory

Multiple mineral sample

Generally, ore properties vary from one mining site to another, and many processing lines are supplied by multiple sites. Guote has developed representative sampling methods tailored to the specific ore properties.

Providing precise testing for over 30 types of ores

The Guote Mineral Analysis Laboratory boasts a full suite of modern, advanced equipment, including crushers, fine grinders, roasters, dryers, vertical ring magnetic separators, flat plate magnetic separators, gravity separators, spectrometers, atomic fluorescence spectrometers, atomic absorption spectrometers, infrared ore analyzers, and testing instruments. It also features a sample crushing chamber capable of performing rock and mineral identification, grinding work index testing, and intelligent laser particle size analysis. Through a variety of mineral processing tests, including gravity separation, magnetic separation, flotation, cyanide leaching and adsorption, bacterial oxidation, acid leaching and wet beneficiation, special beneficiation, heap leaching, tailings thickening, and dry stockpiling, we ultimately determine the optimal mineral processing technology.

Innovative Mineral Processing Tests

Customize unique and innovative testing plans based on the properties of individual ores.

Planning and Design Department

Designs Comply with Canadian NI43-101 and Australian JORC Standards

Guote offers design services not only to Chinese standards, but also to Australian JORC Standards, Valmin Codes, and Canadian NI43-101. For countries and regions in Africa, South America, Central Asia, and Southeast Asia, Guote can design in accordance with Chinese, Australian, Canadian, and local national standards and specifications.

Precise and Innovative Project Design

No two mines are alike. Guote is committed to providing tailored design solutions for your mine.

Comprehensive Expertise and Extensive Experience

Guote Mining Equipment Co., Ltd. has 20 professionals across over 10 specialized fields, including geology, mining, mining machinery, mineral processing, civil engineering, electrical power, water supply and drainage, heating and ventilation, tailings ponds, piping, automation, steel structures, technical economics, and cost estimation. We provide mining engineering design and consulting services for ferrous, non-ferrous, and non-metallic mines with annual processing capacities ranging from hundreds to millions of tons.

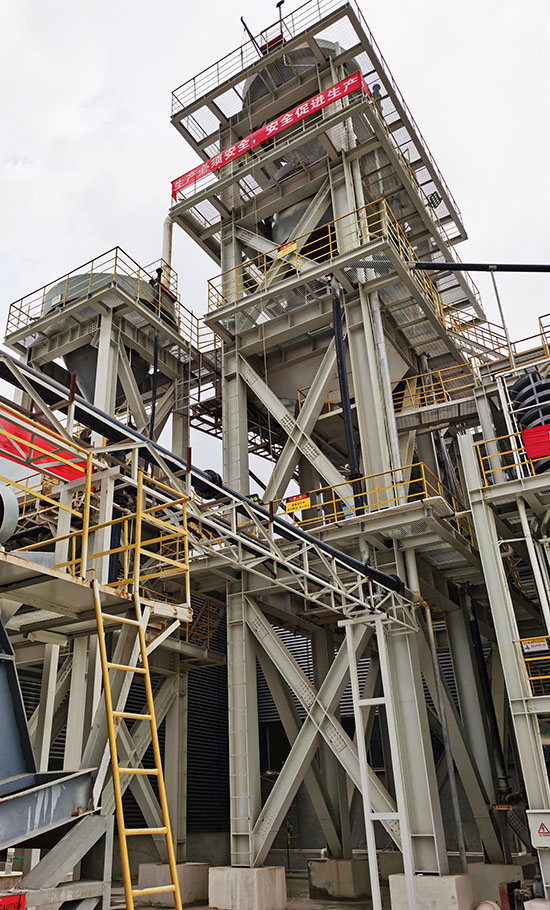

3D Design of Modular Steel Structure Processing Plants and Production Lines

Guote Mining utilizes professional SolidWorks 3D design software and a PDM design management system to provide design services for conventional mineral processing plants, mobile mineral processing plants, 3D mineral processing plants, and modular steel structure processing plant production lines.

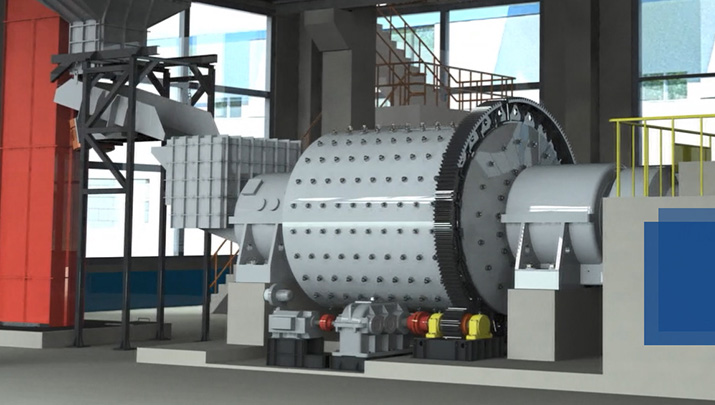

Technical Production Department

Mining Equipment Configuration

Guote provides customers with a wide range of equipment and spare parts needed for mining operations. If certain materials are unavailable locally in certain mining areas, Guote can assist customers in procuring them.

Innovative Machinery and Equipment

Guote Mining Equipment boasts extensive experience in equipment design and has trained a team of technicians proficient in both equipment theory and practice, as well as specialized skills in machining and mineral processing. These technicians have undertaken over 80% of the company's mining equipment upgrades and have applied for numerous national patents.

Strong Equipment Manufacturing Capabilities

Guote offers nearly a thousand types of mineral processing equipment, providing customers with complete sets of main and auxiliary equipment. The company is ISO 9001:2015 and CE certified, and has earned a strong reputation for reliable quality.

High-Standard Accessory Support

For demanding customers, Guote provides internationally renowned brands of motors, reducers, bearings, electrical components, and other accessories.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516