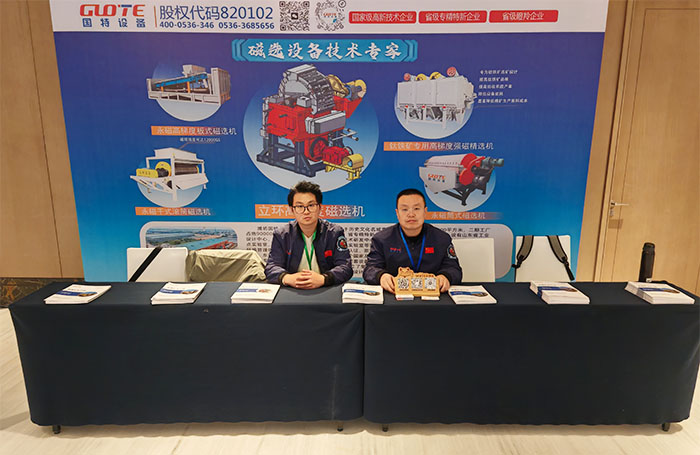

From November 27th to 28th, the 2025 China Vanadium-Titanium Industry Chain Conference was held in Hebei, China. The conference aimed to build an efficient platform for connecting the industry chain and supply chain, strengthen communication and cooperation; deeply explore industry development trends, policy guidance, and technological bottlenecks to achieve the industry’s goals of high-end, intelligent, and green development; plan for future development and guide the industry to seize opportunities; and showcase the latest achievements, cutting-edge technologies, and high-end products of the vanadium-titanium industry to enhance brand influence.

Guote’s ilmenite beneficiation machine plays a crucial role in the vanadium-titanium industry, primarily in the following aspects:

1. Improving ilmenite grade to meet smelting requirements

• High-efficiency separation: Ilmenite often occurs alongside gangue minerals (such as pyroxene and feldspar), resulting in low-grade ore. The beneficiation machine efficiently separates ilmenite from impurities using physical or physicochemical methods (such as gravity separation, magnetic separation, and flotation), increasing the TiO₂ grade from 10%~20% in the primary ore to over 45%~50%, meeting the raw material standards for titanium slag smelting or chloride-process titanium dioxide production.

• Reducing downstream costs: High-grade concentrate significantly reduces energy consumption and auxiliary material consumption in subsequent smelting, improving production efficiency.

2. Optimizing the comprehensive utilization of vanadium-titanium resources

• Co-processing of vanadium-titanium magnetite: Vanadium-titanium magnetite is a major carrier of vanadium-titanium resources in China (e.g., in the Panzhihua-Xichang region of Sichuan), where iron, titanium, and vanadium coexist. The beneficiator can simultaneously recover vanadium-containing iron concentrate during the sorting of ilmenite, providing raw materials for vanadium extraction (such as vanadium slag), achieving “multi-mining from one ore.”

• Tailings Resource Utilization: The sorted tailings can be further recycled to recover other valuable elements (such as cobalt, nickel, chromium, etc.), reducing resource waste.

3. Supporting Key Links in the Titanium Industry Chain

• Titanium Dioxide Production: Titanium concentrate is the core raw material for the production of titanium dioxide using the sulfuric acid or chloride process. The stable operation of the beneficiator ensures the supply of high-quality titanium concentrate, directly affecting the purity and performance of titanium dioxide.

• Sponge Titanium and Titanium Materials: High-grade titanium concentrate, after being smelted into titanium slag or synthesized rutile, can be used to produce sponge titanium and high-end titanium alloys, meeting the needs of aerospace, military, medical, and other fields.

4. Promoting Technological Upgrading and Environmental Protection

• Domestic Production Breakthrough: Its research and application reduce dependence on foreign countries and improve sorting efficiency through automation and low-energy consumption design.

• Reduced Pollution: High-efficiency sorting can reduce tailings emissions, and when combined with environmentally friendly processes (such as acid-free flotation), it alleviates environmental pressure.

The Guote titanium-iron ore beneficiation machine is a key pre-processing link in the vanadium-titanium resource industry chain. Its technological level directly affects the quality of titanium concentrate, the efficiency of comprehensive resource utilization, and the competitiveness of downstream products. Through continuous equipment innovation, significant progress has been made in the sorting of complex associated minerals, providing a solid guarantee for the stable supply of strategic vanadium-titanium resources.

-

PRE

The 4th Northeast Steel Raw Material Market and Mining Technology Development Conference

The highly anticipated "4th Northeast Steel Raw Material Market and Mining Technology Development Co…

-

NEX

The 7th China Mining Industry-University-Research Integration Conference 2025

As green development becomes the core issue of mining transformation, and as industry-academia-resea…

RELATED NEWS

- Guote high-purity sand production line equipment was shipped in its entirety, helping the photovolta…

- Guote Equipment Showcases at the 2nd Panxi Mineral Resources Conference

- Guote Equipment successfully shipped ball mills, wet belt magnetic separator, and sand dryers, contr…

- The 2nd China Shale Oil and Gas Exploration and Development Technology and Equipment Exchange Confer…

- The 7th China Mining Industry-University-Research Integration Conference 2025

- 2025 China Vanadium-Titanium Industry Chain Conference

- The 4th Northeast Steel Raw Material Market and Mining Technology Development Conference

- Technology Leading the Way, Creating the Future! The 9th Quartz Conference 2025

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE